Differences Between Common Vacuum Flange Standards

When designing vacuum systems, understanding the various flange standards is crucial. Three common types are CF, KF, and ISO flanges, each with unique structures, applications, and standards. This article aims to clarify the differences and connections between these flanges to aid in your vacuum system design.

1. CF Flanges

CF Flanges, short for Conflat Flanges, are used in ultra-high vacuum (UHV) applications. These flanges feature a metal seal capable of withstanding high-temperature baking, making them ideal for stringent vacuum requirements.

Specifications:

- Nominal Diameter Sizes: DN16, 40, 63, 100, 160, 200, 250

- Maximum Vacuum: Up to 10^-12 mbar (convert to Pa using online tools if needed)

- Seal Materials: Viton, PTFE, oxygen-free copper, etc.

- Flange Materials: Typically made from 304 or 316 stainless steel

Components:

- Flange

- Metal seal (e.g., oxygen-free copper gasket)

- Fasteners

Usage:

- Ideal for ultra-high vacuum systems

- Commonly used in scientific research, semiconductor manufacturing, and other high-vacuum applications

2. ISO-KF Flanges

ISO-KF Flanges are quick-release flanges used in vacuum systems. They consist of paired KF flanges, an O-ring, a centering ring, and a clamp. These flanges are easy to assemble and disassemble by hand without tools.

Specifications:

- Nominal Diameter Sizes: DN10, 16, 25, 40, 50

- Manufacturing Standards: DIN 28403, ISO 2861

- Maximum Vacuum: Up to 10^-8 mbar

- Seal Materials: Viton, Buna, Silicone, EPDM, aluminum, etc.

- Flange Materials: Typically made from 304 or 316 stainless steel

Components:

- Flange

- O-ring

- Centering ring

- Clamp

Usage:

- Suitable for small-sized vacuum applications

- Commonly used in laboratory settings and small vacuum systems

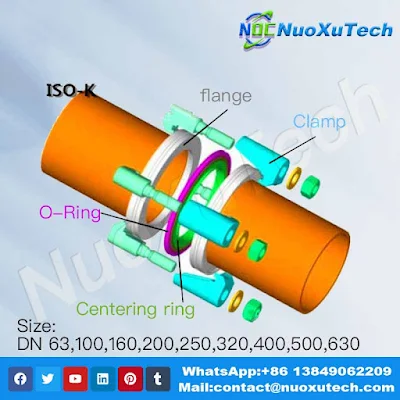

3. ISO Flanges

ISO Flanges are versatile and can be used in applications ranging from atmospheric pressure to high vacuum. They are suitable for systems requiring frequent assembly and disassembly, especially for pipes larger than 50mm in diameter.

Types and Specifications:

ISO-K Flanges:

- Nominal Diameter Sizes: DN63, 100, 160, 200, 250, 320, 400, 500, 630

- Manufacturing Standards: DIN 28404, ISO 1609

- Maximum Vacuum: Up to 10^-8 mbar

- Seal Materials: Viton, Buna, Silicone, EPDM, aluminum wire, etc.

- Flange Materials: Typically made from 304 or 316 stainless steel

- Components: Flange, clamp, O-ring, centering ring

ISO-F Flanges:

- Nominal Diameter Sizes: DN63, 100, 160, 200, 250, 320, 400, 500, 630

- Manufacturing Standards: DIN 28404, ISO 1609

- Maximum Vacuum: Up to 10^-8 mbar

- Seal Materials: Viton, Buna, Silicone, EPDM, aluminum wire, etc.

- Flange Materials: Typically made from 304 or 316 stainless steel

- Components: Flange, O-ring, centering ring, bolts (for securing)

Usage:

- Suitable for larger vacuum systems

- Commonly used in industrial and research applications

By understanding the distinct features and applications of CF, KF, and ISO flanges, industries can make informed decisions to optimize their vacuum systems. NuoXuTech offers a wide range of high-quality vacuum products tailored to meet specific needs.

Contact Us

For more information, please visit our website www.nuoxutech.com or contact us at contact@nuoxutech.com. You can also reach us on WhatsApp at +86 13849062209.Our team is ready to provide you with professional service and support.

Keywords: vacuum flanges, CF flanges, KF flanges, ISO flanges, vacuum system design, industrial vacuum solutions, NuoXuTech

Comments

Post a Comment