How Does The Rotary Vane Pump Work?

Rotary vane vacuum pumps are essential components in numerous industrial and scientific applications, providing reliable and efficient vacuum creation. These pumps consist of a pump body, rotor, vanes, end covers, springs, and other components. This article explains the working principle and highlights the distinctive features of rotary vane vacuum pumps.

1. Working Principle of Rotary Vane Vacuum Pumps

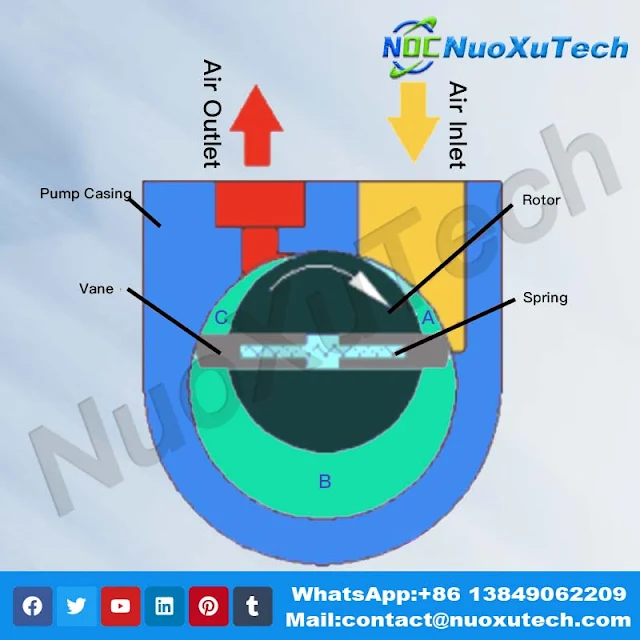

The rotary vane vacuum pump operates by using a rotor installed eccentrically within the pump chamber. The outer circumference of the rotor is tangent to the inner surface of the pump chamber, with a small clearance between them. Two vanes, equipped with springs, are placed within slots in the rotor. As the rotor rotates, centrifugal force and spring tension keep the vane tips in contact with the inner wall of the pump chamber. This rotation causes the vanes to slide along the chamber wall, creating an enclosed, crescent-shaped space that is divided into three parts: A, B, and C.

When the rotor rotates in the direction indicated by the arrow:

- Space A: This space, connected to the intake port, expands as the rotor rotates, resulting in a decrease in pressure. This creates a suction process that draws gas into the pump.

- Space B: As the gas moves from space A to space B, it becomes compressed. The volume of space B gradually decreases during the rotation, leading to a compression process.

- Space C: This space is connected to the exhaust port. As the rotor continues to rotate, space C's volume decreases further, compressing the gas. When the gas pressure exceeds the exhaust pressure, the exhaust valve opens, allowing the compressed gas to pass through the oil layer in the oil tank and be expelled into the atmosphere.

This continuous rotation of the rotor results in a consistent suction and compression cycle, allowing for continuous pumping action.

For enhanced performance, rotary vane vacuum pumps can be configured as two-stage pumps:

- Two-Stage Rotary Vane Vacuum Pump: If the exhaust gas is directed through a passage to a second stage (low vacuum stage), it is further compressed and then exhausted into the atmosphere. This configuration allows the total compression ratio to be distributed across two stages, thereby increasing the ultimate vacuum level.

2. Key Features of Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are known for several unique characteristics that make them highly effective in vacuum applications:

- Compact Size and Lightweight: These pumps are designed to be small and lightweight, making them easy to install and transport.

- Low Noise Levels: Rotary vane vacuum pumps operate quietly, making them suitable for environments where noise reduction is essential.

- Gas Ballast Valve: Equipped with a gas ballast valve, rotary vane pumps can remove small amounts of water vapor. When the gas being pumped has a relative humidity greater than 90%, the gas ballast valve should be opened.

- Automatic Anti-Backflow Check Valve: These pumps have an automatic anti-backflow check valve, making them easy to start and preventing backflow of oil into the system when the pump is stopped.

- Continuous Operation: Rotary vane vacuum pumps can operate continuously under ambient temperatures ranging from 5°C to 40°C, provided the inlet pressure is below 1.3 x 10³ Pa.

- Short Atmospheric Operation Duration: If the pump's intake port is continuously exposed to the atmosphere, the operation should not exceed one minute to avoid damage.

- Not Suitable for Certain Gases: Rotary vane vacuum pumps are not suitable for pumping gases that are corrosive to metals, react chemically with pump oil, contain particulate dust, have excessively high oxygen content, are explosive, or are toxic.

Rotary vane vacuum pumps are widely used due to their reliability, compact design, low noise levels, and ability to handle small amounts of water vapor. However, they are not suitable for pumping corrosive, explosive, or highly reactive gases. Understanding the working principle and features of these pumps is crucial for selecting the right pump for specific applications and ensuring optimal performance in various industrial processes.

Contact us

For more information about How Does The Rotary Vane Pump Work, contact Nuoxutech at contact@nuoxutech.com or visit our website www.nuoxutech.com .You can also reach us on WhatsApp at +86 13849062209.Our team is ready to provide you with professional service and support.

Keywords:Rotary vane pump, Rotary vane, vacuum pump,nuoxutech,Rotary vane vacuum pump, vacuum technology, vacuum pump working principle, gas ballast valve, two-stage vacuum pump

Comments

Post a Comment